At present, most of the logistics express delivery industry uses ordinary express delivery documents. By means of manual entry, the sales records are usually brought back by the business personnel, which is inefficient, error-prone and inefficient. With the development of the economy, the logistics express delivery business is increasingly busy, the number of bills has increased, manual inspection and management have not adapted to the requirements of the development of the current era, and the industry needs an advanced, high-efficiency and perfect cargo tracking management system. The advantages of this system are advanced is not only management thinking, also must rely on advanced logistics automation equipment and technology, and rely on excellent information system platform to play a better role. Automation equipment and technology can improve work efficiency and reduce manpower operation error rate from hardware.

Warehouse management solution

Has your business encountered the following problems?

When looking for goods in the warehouse, it takes time and effort and is often not found. It is not clear how much inventory is in the warehouse, and it is not clear where to store it. It takes time to count the goods. Inbound storage, it takes a long time to get out of the warehouse, which affects efficiency.

The above problems will seriously affect the efficiency of enterprise product logistics transportation, resulting in management confusion and improving the management cost of enterprises.

The barcode (RFID electronic tag) warehouse management software system can solve the above problems. Through the software of the data center, you can accurately locate the specific storage location of each item, accurately count the quantity/specification of the goods, and accurately manage each person's warehousing and delivery process.

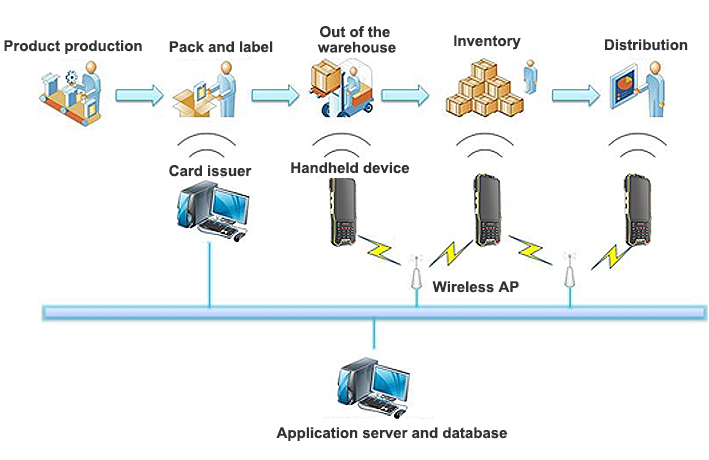

The system uses barcode/RFID electronic label technology, combined with ERP visualization database software, to form a set of visual tracking from warehousing, transfer, inventory, and outbound. The system is divided into central ERP bar code data management, and the handheld client manages two parts. The main function of the bar code warehouse management system is to accurately manage the cargo, accurately locate the cargo storage location, speed up the cargo transit speed, and eliminate the loss of goods or property losses caused by human factors.

System Components

1.Barcode/RFID Electronic Label:

In manufacturing, bar code/electronic tags are used primarily in asset, and personnel identification and monitoring. The markers mainly include tools, equipment, property inventories, and related personnel. Labels can be designed in a variety of styles, such as card, strip, wristband, etc., according to customer needs.

Barcode management software

Software sub-database center management software, handheld management software. Module functions include: storage management, transfer management, inventory management, cargo search and outbound management.

2.Data collector

The optional function is barcode/RFID acquisition, and the wireless communication uses WIFI function. It is mainly used to collect barcode/RFID data, and the collected data is transmitted to the database center through the WIFI wireless base station.

3.Wireless LAN

WIFI wireless LAN, mainly used as a bridge between data collectors and central management software. It is wireless and convenient for on-site use.

4.In and out of the warehouse process

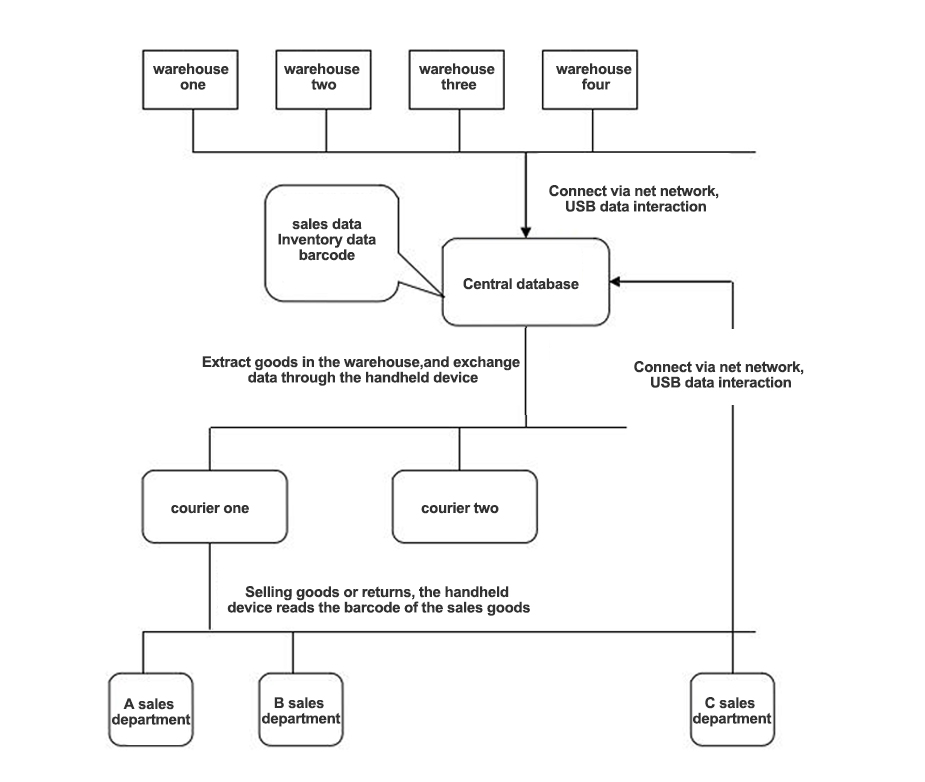

Warehouse distribution system solution

The main functions are to realize the management of goods out of the warehouse, the transfer of goods between warehouses, and the sale of unfinished returns and exchange management. Use bar code to manage the flow of each item, and check the outbound records of the items that have not been sold by the customer.

According to customer requirements, the outbound management system is an automated identification management system that integrates RFID functions.

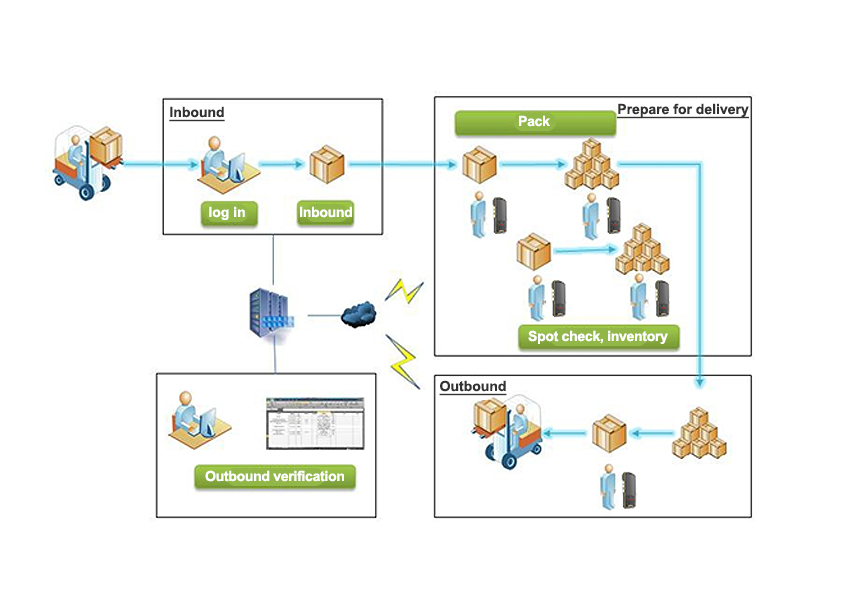

1. Package and write information

Before the goods are put into storage, the packing area is set, and the data is transmitted in real time through the terminal. According to the actual warehouse management application requirements, the corresponding items will be packaged into independent packages according to the specified quantity. The corresponding bar code will be pasted and the information of the bar code on the item will be collected. When the package is completed, it will be packaged into a single piece and a single piece of bar code. Information collection.

1. In and out warehouse inspection

Entry

When the goods are packaged and entered into the warehouse, the information of each piece of goods is read by the reader, and then the quantity is calculated by the computer storage management information system, and stored in the corresponding position according to requirements.

Outbound

The deliveryman picks up the goods, extracts the whole item or the single item inthe whole item according to the need, and then delivers the goods to the delivery port. At this time, the port reader reads whether the single piece or single product barcode information is accurate. The storage management information system calculates the quantity and verifies the correct shipment.

2. Deliveryman to the sales department

Delivered to the sales department, according to the sales department, unload the corresponding goods, read the barcode to record the unloading quantity; and record the quantity of the return and replacement items required by the sales department. The name and batch of the delivery can be checked during the return process.

3. Delivery completed

The delivery is completed and returned to the warehouse, and the data is docked with the warehouse. Sales situation corresponding to the goods, return status, unsold, returned items through the bar code, re-input inventory; then through the computer storage management information system to calculate the quantity, according to the requirements to store the corresponding location

Report analysis

Perform statistical analysis on the data of the system to generate related reports.

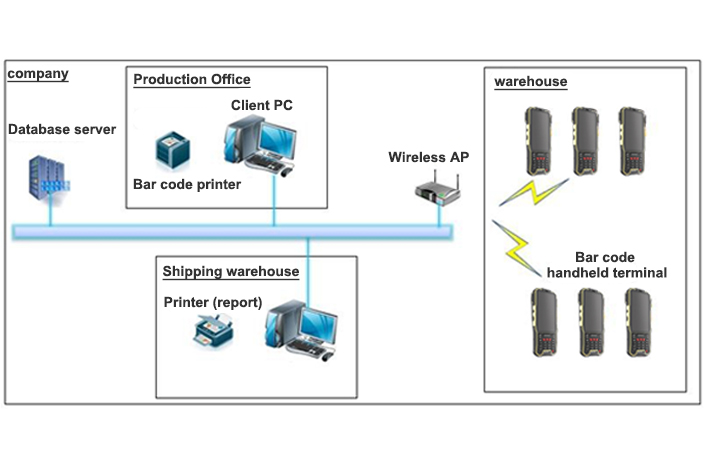

Hardware

Barcode: Record basic information such as product model, name, and category.

Handheld: Read the barcode to record the library and warehousing information, and upload the data to the central database via USB or GPRS (auxiliary transmission).

Software

Management Center Subsystem;

The management center subsystem is the core system of cargo management. Through this system, the functions of cargo barcode database, user authority management, cargo classification and query management are established.

Data acquisition subsystem

The data acquisition subsystem scans the barcode data by the handheld.

Express delivery business solution

With the rapid development of the national economy and society, the intensity of development and competition in the logistics industry has never been more prevalent, and customer demand has also shown a diversified and personalized development trend. The existing logistics system has become a requirement for this development. The power is not enough, so it is urgent to build an integrated logistics information platform. The automatic identification technology is an important method and means for automatically reading and automatically inputting information data into the computer, which provides us with an effective means for fast and accurate data acquisition and input.The program integrates with the computer system, uses bar code and RFID automatic identification technology, and mobile handheld terminal technology to build an integrated logistics information processing platform, fully realizes the entry and sharing of the express item information; provides the user with full-time real-time dynamic tracking query; Monitoring and management of information, system operation status, and business operation quality, and providing real, effective, and timely management and decision support information for managers at all levels to provide support for the rapid development of business.

The mobile data terminal is a bar code collection device that combines bar code technology, palmtop technology and GPRS technology. In the express logistics project, help the courier company to serve customers accurately and quickly. In the express delivery business, how to accurately grasp the tracking of the express delivery process, effectively analyze and manage the work of the courier. As well as the customer's timely knowledge of the shipment status of the goods they deliver, these are an important factor in evaluating the level of the courier company. With Internet technology, bar code technology, SMS platform technology and new GPRS technology, we can quickly grasp information, speed up service accuracy, improve work efficiency, reduce error rate and reduce operating costs.

Express document barcode identification

Use a bar code label printer to print or print a shipment document, and uniquely identify each item or letter so that the courier system can track the shipment and the customer can query the shipment.

Express shipment information collection and transmission

The mobile data terminal is used for barcode scanning in the process of express mail collection, transportation, delivery, etc., and the data information is transmitted to the information platform through the wireless G RS network

Information platform value-added services

The information platform conducts statistics, management and distribution of logistics system operation information, provides various customized value-added services for express delivery companies and users, realizes mobile computing management of logistics express delivery business, and enhances the competitive advantage of express delivery.

Three business functions, and realize: a number of practical business modules such as picking up goods at home, automatic loading of employees, automatic number picking, confirmation of on-site status, automatic reading of parcel number, fast delivery, signing, delivery process monitoring, etc.

The advanced logistics automation equipment and technology of the express delivery industry can be better played by relying on the excellent information system platform. The automation equipment and technology can improve the efficiency of work and reduce the error rate of human operation, while the information platform is soft. The logistics company provides a large amount of management data information for use as a basis for management decisions. The integration of automation equipment and technology with information platforms, especially for mobile terminals, can greatly improve the timeliness, accuracy and real-time availability of information.